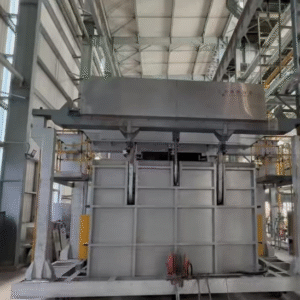

Core Function:

As a key cleaning device in the zinc pot area of hot-dip galvanizing lines, it is specifically designed for efficiently extracting and removing zinc dross and surface skimmings from molten zinc. With reliable high-temperature and corrosion resistance, it ensures molten zinc purity, significantly improves galvanized surface quality, while reducing manual cleaning intensity and safety risks.

Application Fields:

· Hot-dip Galvanizing Lines (CGL)

· Galvalume Lines

· Zinc Alloy Smelting and Casting

Key Performance Parameters:

· Pump Body Material: Heat-resistant alloy steel, Special ceramic composites

· Operating Temperature: 400℃ – 660℃ (matched to molten zinc temperature)

· Power Configuration: Electric/Pneumatic drive (Explosion-proof option available)

· Key Performance: Excellent thermal shock resistance, corrosion resistance to molten zinc, and wear resistance

· Cleaning Capacity: 5 – 30 m³/h (Depending on model and working conditions)

· Service Life: 1 – 3 Years (Primarily depends on usage frequency and maintenance)