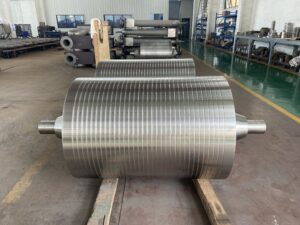

Core Function:

As a heart component in hot-dip galvanizing/aluminum lines, it is permanently submerged in molten metal to provide stable steering and support for the strip. Its surface quality and stability directly determine coating uniformity and final product surface quality.

Application Fields:

· Hot-dip Galvanizing Lines (CGL)

· Hot-dip Aluminizing Lines

· Continuous Coating Lines

Key Performance Parameters:

· Main Materials: Stainless Steel, Tool Steel, Special Ceramics & Composite Materials

· Operating Environment: Submerged in 400°C – 660°C molten zinc/aluminum

· Key Performance: Superior resistance to molten metal corrosion and creep

· Specifications: Custom-sized to fit various production line layouts

· Service Life: 3 – 24 Months (Depending on process, material, and maintenance)