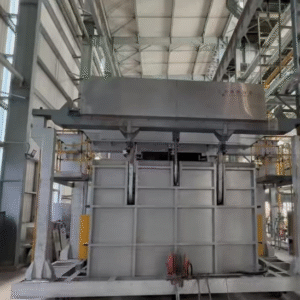

Core Function:

As a critical gas-tight connection between the annealing furnace and zinc pot in galvanizing lines, it employs special sealing structures and controlled protective atmosphere to prevent oxygen ingress, ensuring the strip enters the zinc pot under oxidation-free conditions. It is the core component for achieving high-quality galvanized surfaces and stable production processes.

Application Fields:

· Hot-dip Galvanizing Lines (CGL)

· Galvalume Lines

· High-Strength Steel Annealing Lines

Key Performance Parameters:

· Structure Type: Water-cooled jacket/Refractory lined structure

· Main Materials: Heat-resistant stainless steel/Special refractories

· Operating Temperature: 400℃ – 600℃ (zinc pot contact area)

· Sealing Method: Nitrogen sealing/Mechanical labyrinth sealing

· Key Performance: Excellent air tightness, zinc corrosion resistance, thermal stability

· Service Life: 1-5 years (depending on operating temperature and maintenance frequency)